Product Training

Modul OEE & Process Analysis

Create transparency - recognize potential

Why PromasTrain?

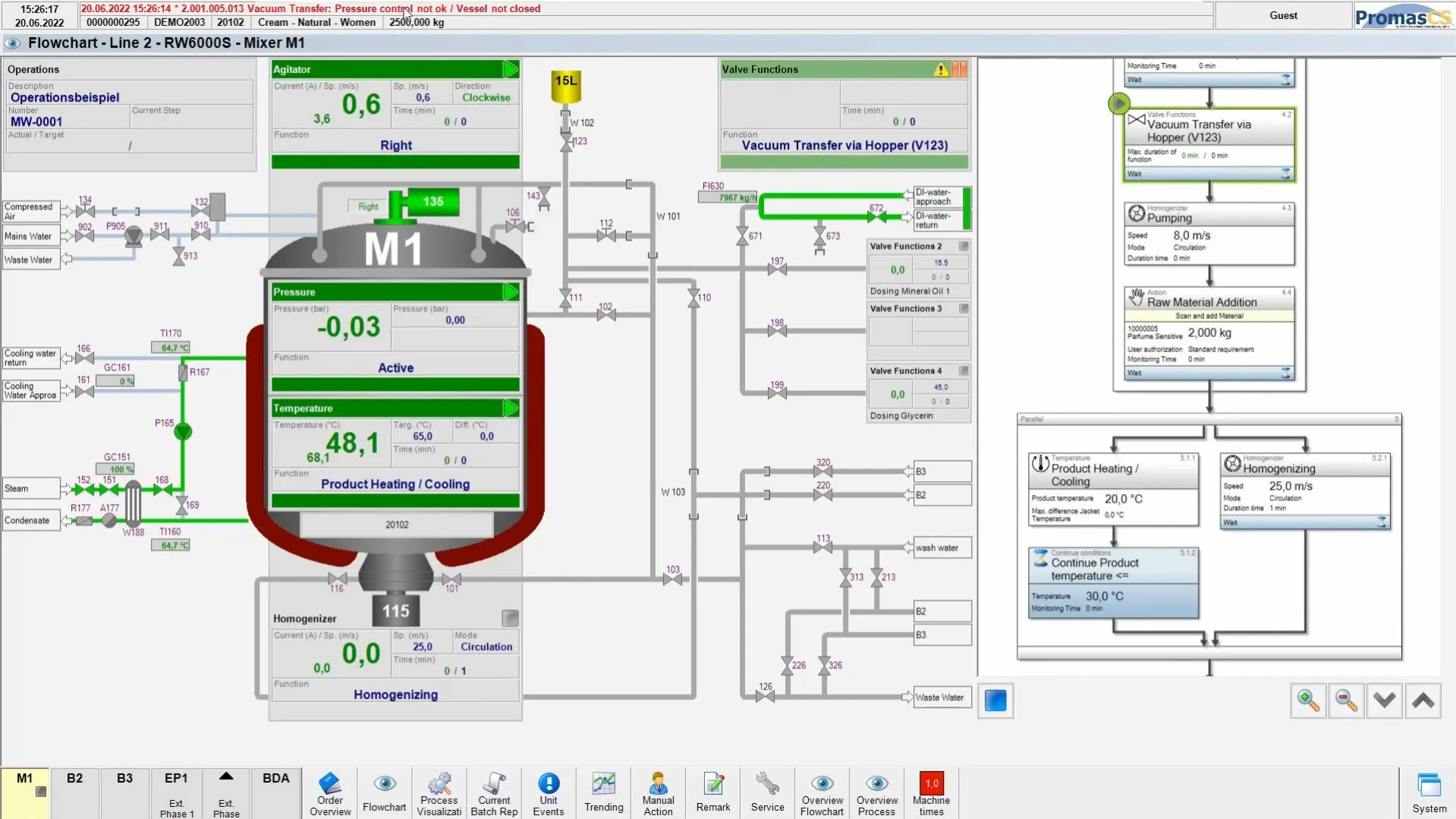

Make better decisions based on reliable data! PromasTrain gives your team the knowledge to analyze processes thoroughly, correctly interpret OEE metrics, and initiate targeted optimizations – based on facts rather than guesswork.

Training Content:

- Analysis and optimization of process runtimes down to the step level.

- Identification of optimization potential using IPC trends, Gantt charts, Pareto loss analysis, and heat maps.

- Evaluation of OEE metrics: availability, performance, quality rate, as well as machine and personnel times.

- Interpretation of disruption data (MTBF/MTTR) and production volumes.

- Use of dashboards for KPIs or water consumption to derive targeted improvement measures.

Your benefits:

- Targeted process optimization through sound analyses and key performance indicators.

- Targeted exercises for quick implementation in everyday work.

- Training tailored to your company and your requirements.

- Practice-oriented training: Our experienced trainers impart knowledge based on real-life application cases.

PromasCS OEE & Process Analysis Training

- Duration: 1 day

- Location: In-Person / Online

- Language: German / English

- Participants: Inhouse up to 10

Our modules - suitable for your requirements

Whether automated process control with batch, audit trail, OEE analysis, recipe management, or in-depth process evaluation - with our training modules, you will specifically build the know-how that will truly help you advance in your production environment.

Select the appropriate module and submit your booking request directly.

We coordinate the training content, location and scope individually with you.

Do you have anymore questions?

Call us or email us.

+49 4471 9293-0