Built-In HMI, Batch & Automation Control

The MES that runs your plant - not just your schedule

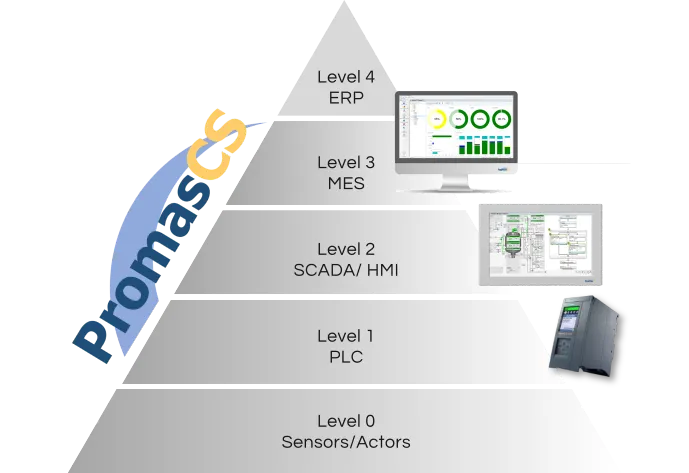

PromasCS – the modular MES for automating production processes for manufacturers in the pharmaceutical, chemical, cosmetics and food industries.

- One system for everything

A system that seamlessly connects the control level, the control system (PCS/SCADA), and the MES – from raw material delivery to final packaging. This sustainably reduces training requirements for operating personnel.

- Increase productivity & reduce effort

PromasCS maximizes efficiency through a high degree of automation, ensures consistently high quality thanks to reproducible batch processes, and creates transparent, optimized production processes.

- Intuitive & efficient

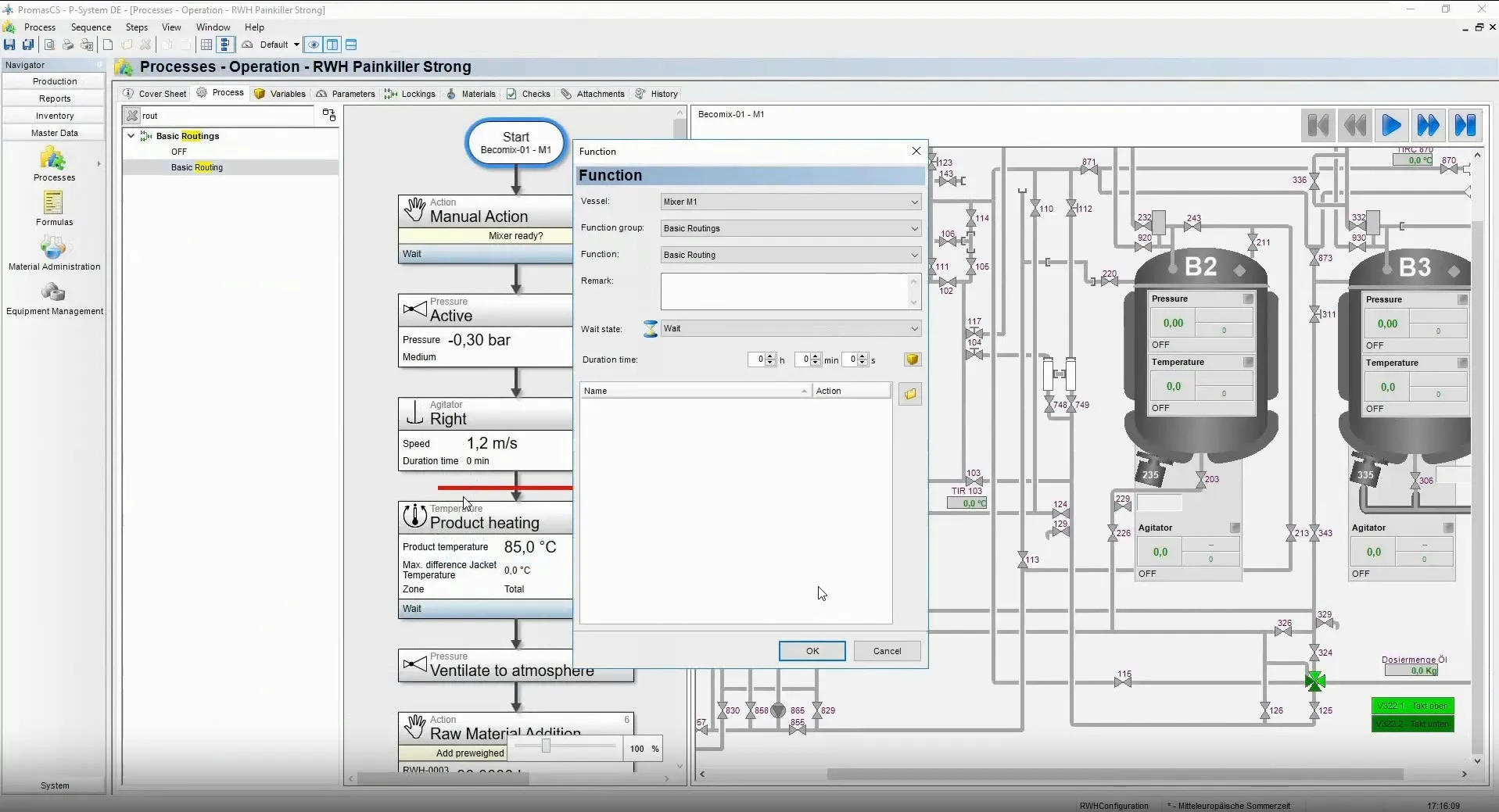

Thanks to the user-friendly interface, getting started is quick – even without any programming knowledge. Production processes can be designed efficiently and intuitively directly on the system's control panel. The highly standardized architecture and no-code approach enable easy configuration of entire process and cleaning sequences.

- Scalable & flexible

From a small laboratory system to a complete production line – PromasCS grows with your requirements and can be flexibly configured and purchased thanks to its modular design.

- Open & networkable

A standardized interface (API) allows ERP systems, cloud applications, and business intelligence tools such as MS Power BI and many other solutions to be seamlessly connected.

- Validated & Qualified

PromasCS is based on a validated, well-documented software architecture with integrated electronic batch documentation (EBR) according to GMP/FDA 21 CFR Part 11 – this significantly reduces the validation effort in customer projects.

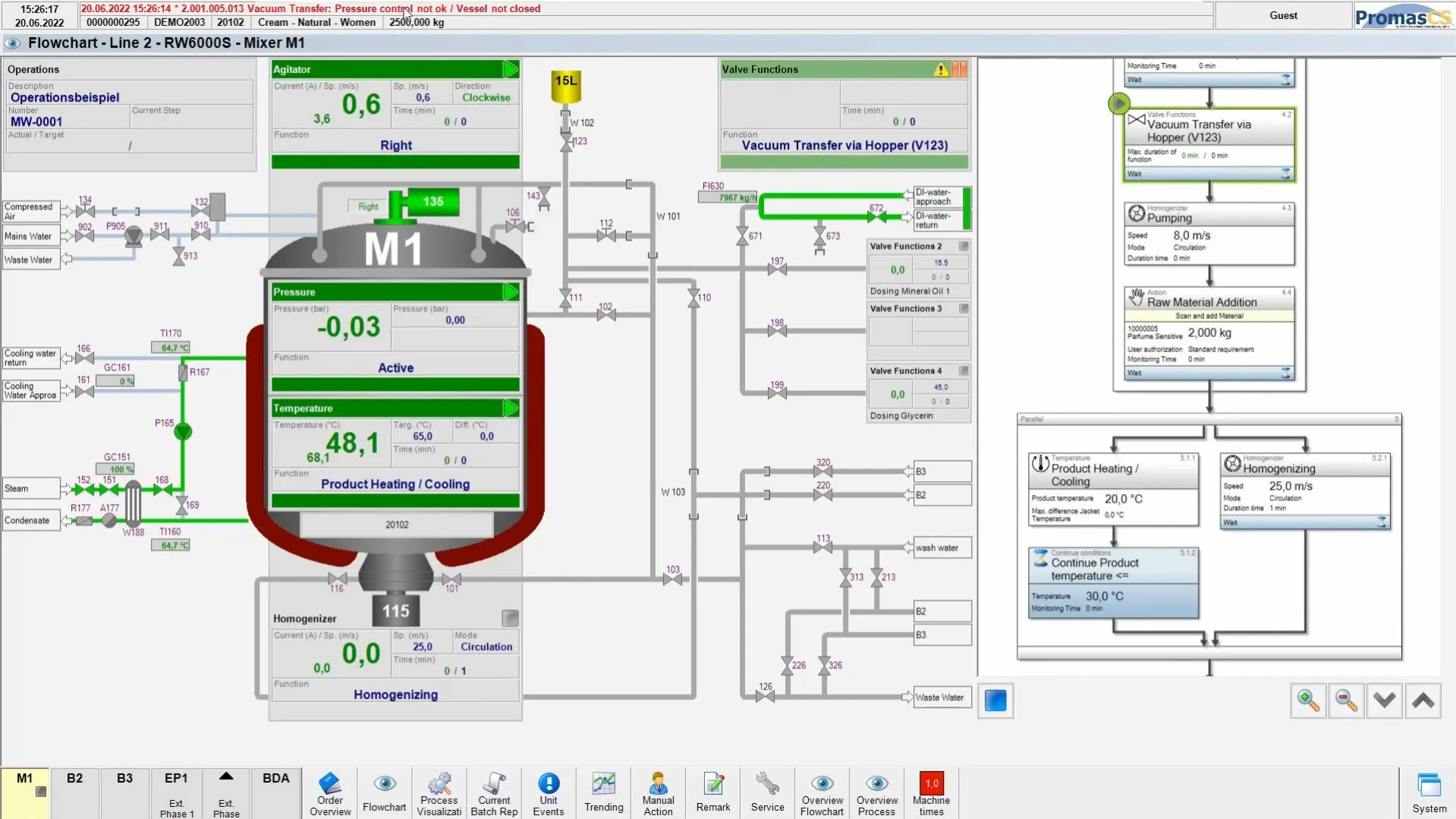

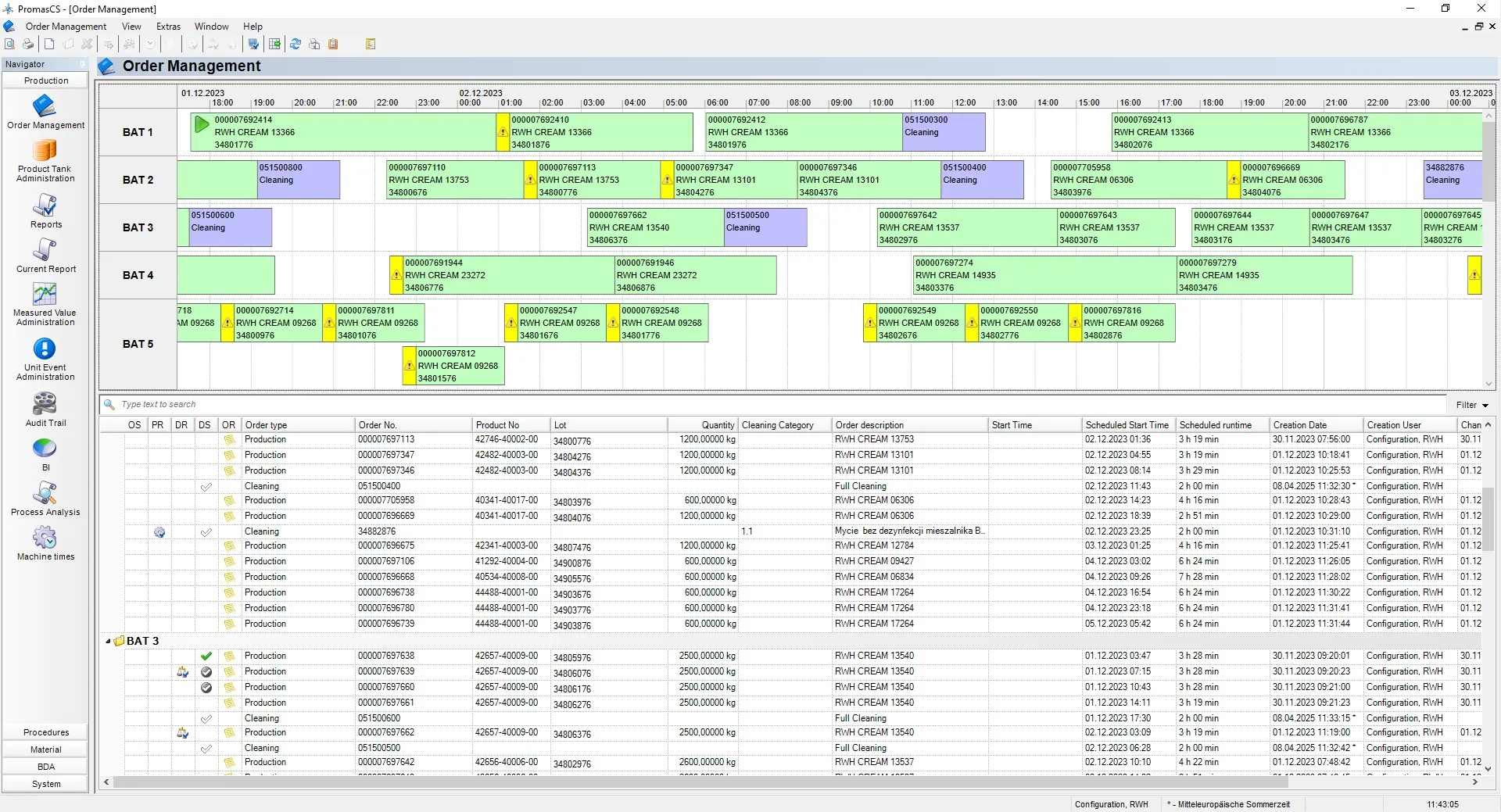

All in one system – control, control system & MES seamlessly integrated

PromasCS combines the control level, the process control level (operating and monitoring) and the Manufacturing Execution System (MES) in a single, fully integrated platform.

Consistent data – from the field device to the management level

All data throughout the production process is centrally recorded, evaluated, and analyzed – from measurement data acquisition at the field level to organization and visualization at the MES level. The result: maximum transparency and seamless integration across all levels.

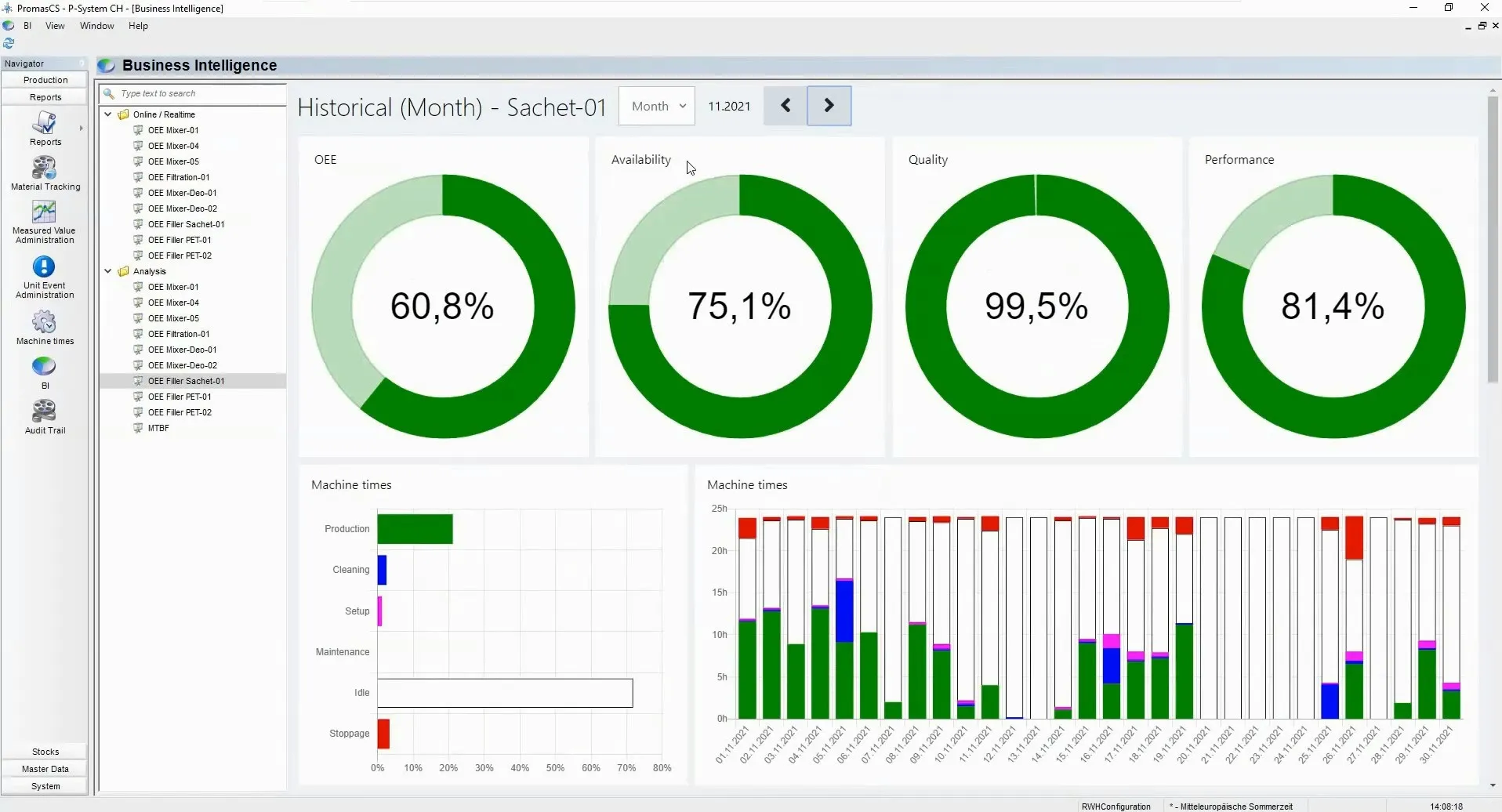

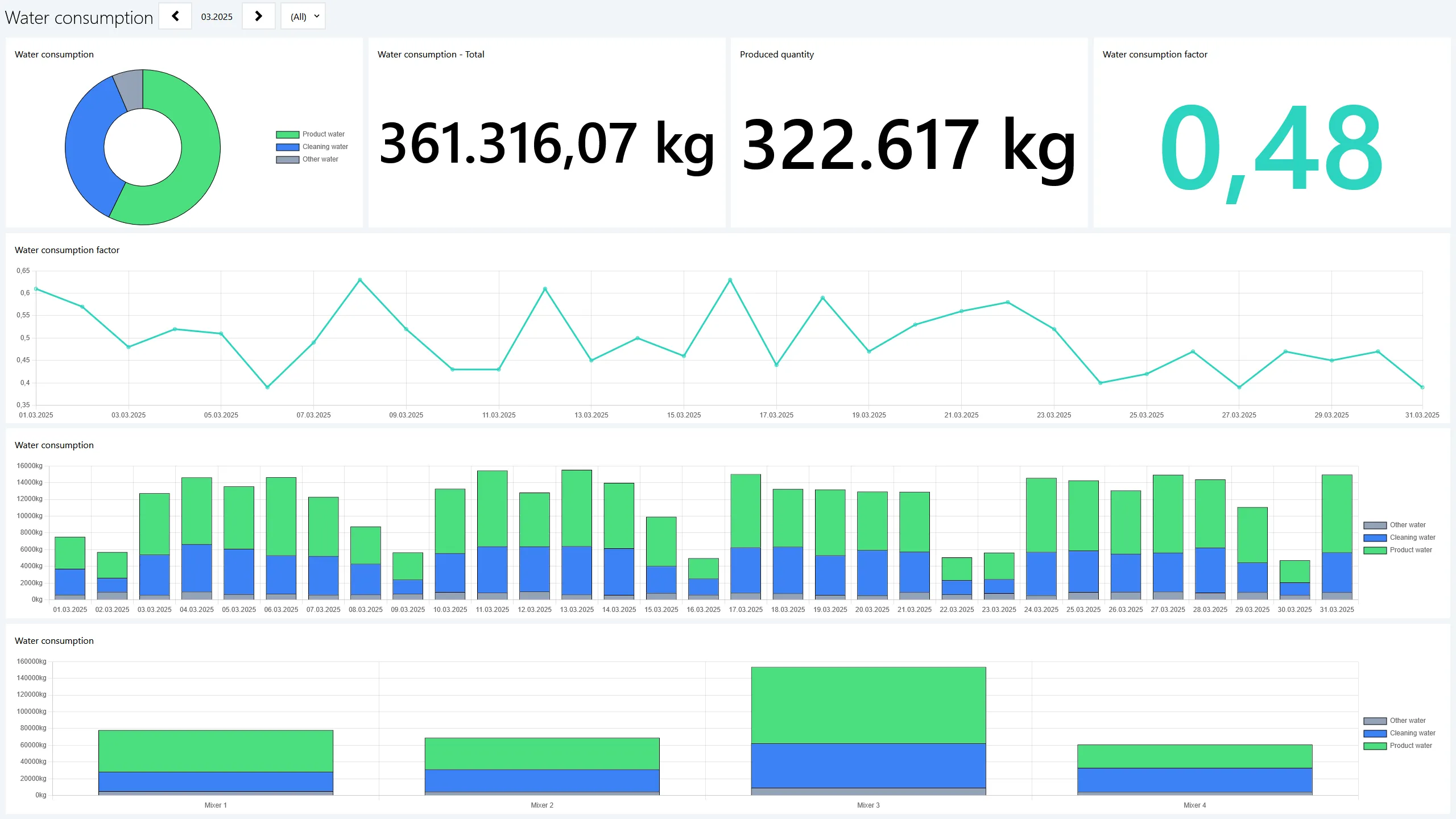

Integrated Business Intelligence – for transparency in production

The integrated, web-based BI module enables simple and user-friendly visualization of your production data. Dashboards, key performance indicators, and analyses provide valuable insights – for informed decisions, continuous improvement, and greater efficiency in production.

The strengths of PromasCS at a glance

Intuitive complete solution

PromasCS offers an intuitive, modern and configurable complete solution that is easy to use. Thanks to the user-friendly interface, our solution enables system users to get used to it incredibly quickly. Our principle is Simple but Awesome!

No-Code Process engineering

Would you like to automate your process yourself but have no programming knowledge? No problem with PromasCS. Thanks to the highly standardized architecture, you can design your processes yourself and define complete production processes using drag-and-drop and a no-code approach - directly on site at the system's control panel.

Teach-In

Our innovative teach-in function enables the system operator to carry out the process manually. Thanks to our teach-in function, this is recorded using macros and an automated, retrievable process is generated from it. This means you can run through your 'Golden Batch' manually and then have it run automatically.

Scalable

PromasCS is scalable and grows with YOUR requirements – from a simple plant control system to a complete MES system. Our solution adapts flexibly to your individual needs and offers you maximum adaptability and future security.

Tailored

PromasCS is specifically tailored to the demanding production processes in the pharmaceutical, chemical, cosmetic and food sectors. With our many years of industry experience, we develop tailor-made solutions that meet the highest quality and safety standards and optimally support your production processes.

Electronic Records

PromasCS offers electronic recording and documentation (EBR) according to FDA 21 CFR Part 11. Our solution ensures complete, secure and compliant recording of all production data, thereby meeting the highest quality and safety standards.

Minimal validation

Our fully qualified basic software guarantees minimal validation effort in the project. With PromasCS you save valuable time and resources because our solution has already been comprehensively tested and qualified to meet the highest quality and safety standards.

Developed from practice

PromasCS was developed based on the experience and requirements of production and practice. Our solutions are practice-oriented and arise from in-depth knowledge of the real challenges in production in order to offer you reliable and efficient automation.