Allgemeine Informationen

- Fertige, durchgängige, konfigurierbare und einfach zu bedienende Komplettlösung zur praxisnahen Integration und Automation aller Produktionsbereiche

- Zugeschnitten auf Produktionsprozesse im Pharma-, Chemie-, Kosmetik- und Lebensmittelbereich

- Skalierbar von einer einfachen Maschinensteuerung hin zu einem vollständigen MES-System

- Vereint MES- & PLS und SCADA-Funktionen in einem System

- Elektronische Aufzeichnung und Dokumentation (EBR) entsprechend FDA 21 CFR Part 11

- Fertig qualifizierte Basissoftware garantiert einen minimalisierten Validierungsaufwand im Projekt

- Entwickelt aus den Erfahrungen und Anforderungen der Produktion und Praxis

- Seit 2005 weltweit mit mehr als 1500 Installationen im produktiven Einsatz

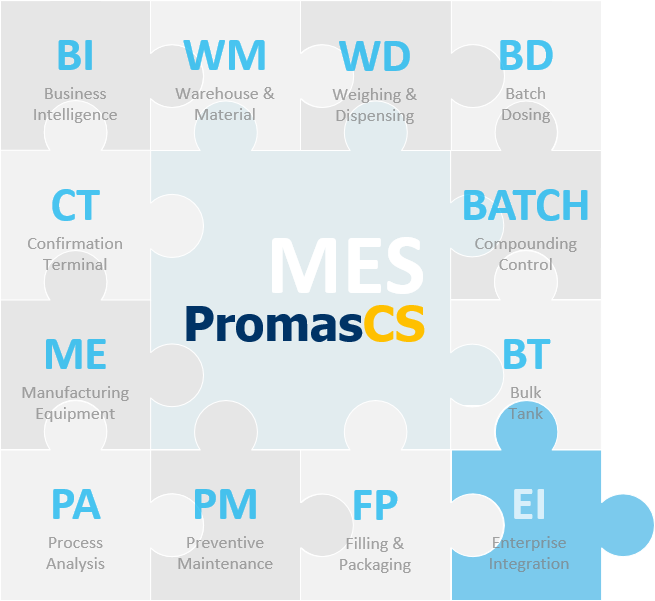

Die Module von PromasCS

BD – Rohstofftanks

- Vollständig integriertes Rohstofftankmanagement zur Annahme und zentralen Bereitstellung von Rohstoffen

- Mengenerfassung und automatische Anlieferungsbuchung

- Verwaltung, Berechnung und Überwachung vom Haltbarkeits- / Verwendbarkeitsdatum

- Vollautomatisierte Reinigungssteuerung über Visual Process

- Überwachung des Reinigungs- und Sterilisationsstatus

BD – Zentrale Rohstoffdosierung

- Vollständig integriertes Dosiersystem zur zentralen Rohstoffversorgung von Mischlinien und Entnahmestellen

- Koordination / Priorisierung der Dosieranforderungen

- Überwachung und Verriegelung in Abhängigkeit vom Haltbarkeits- / Verwendbarkeitsdatum

- Automatische Sperrung der Rohstofftanks

WD / WM – Lagern / Wiegen / Bereitstellen

- Unterstützung variabler Wirkstoffkonzentrationen

- Berücksichtigung von Ingredienzen zuvor verwogener Rohstoffe

- Priorisierung der Entnahmegebinde in Abhängigkeit vom Haltbarkeits- / Verwendbarkeitsdatum

- Systemgeführte Kalibieranweisungen oder Arbeitsanweisungen

- Workflow führt den Bediener durch den Wiegeprozess

CT – Elektronisches Bestätigungsterminal

- Integration von Bestandsanlagen in die papierlose Dokumentation (EBR) – ohne Eingriff in die vorhandene Automation

- Elektronische Herstellanweisung führen den Bediener Schritt für Schritt durch den Herstellprozess

- Rohstoffquittierung per Barcode zur Sicherstellung der Rohstoff- / Chargen-Zuordnung

BATCH – Compounding

- Skalierbare / festen Ansatzgrößen für reproduzierbare Prozesse

- Automatische Steuerung von Produktions- und Reinigungsprozessen

- Verriegelung verwendeter Betriebsmittel entsprechend Status und Produkt- / Reinigungsmatrix

- Abfrage / Änderung des Betriebsmittelstatus direkt im Prozesses

- Lückenlose Dokumentation sämtlicher Produktionsschritte (EBR)

BT – Lagertanks

- Einlagerung von Produktionschargen (Bulk-Ware) in stationäre oder mobile Bulktanks

- Verwaltung, Berechnung und Überwachung vom Haltbarkeits- / Verwendbarkeitsdatum

- Unterstützung einer vollautomatisierten Reinigungssteuerung über Visual Process

- Überwachung des Reinigungs- und Sterilisationsstatus

FP – Abfüllung / Verpackung

- Vollständig integrierte Versorgung von Abfüllanlagen

- Automatische Verriegelung mit Qualitätsfreigabe und Reinigungsstatus

- Definition und Identifikation (Barcode) von Verpackungsmaterialien

- Betriebsmittelidentifikation (Barcode) zur Rüstung der Abfüllanlage

- Verwaltung elektronischer Anweisungen für Rüst-, Abfüll- oder Reinigungsprozesse

PM – Wartung & Instandhaltung

- Verwaltung von Wartungs- und Instandhaltungsaufgaben in Abhängigkeit von Betriebsstunden, Schaltspielen oder zeitlichen Intervallen

- Erhöhung der Betriebssicherheit, optimierte Austauschintervalleund Reduktion ungeplanter Stillstände

- Einsparung von Zeit und Materialaufwand

- Hinterlegung von Arbeitsanweisungen und technischen Dokumenten zu Aufgaben oder Betriebsmitteln

- Systemgestützte Dokumentation durchgeführter Tätigkeiten

ME – Betriebsmittel

- Vollständig integrierte Betriebsmittelverwaltung zur Darstellung und Überwachung der zur Herstellung benötigten Betriebsmittel

- Online-Überprüfung des Betriebsmittelstatus während des Herstellprozesses

- Systemgeführte Arbeitsanweisungen

- Betriebsmittelidentifikation (z.B. Barcode, RFID)

MBR (Master Batch Record)

Die Erstellung eigener Reinigungs- und Produktionsprozesse erfolgt mit hilfreicher Unterstützung und Visualisierung der HMI-Fließbilder und der grafischen Flussdiagramm-Darstellung ohne jegliche Programmierkenntnisse – einfach per Drag & Drop. Die Möglichkeit der Simulation und der Plausibilitätsprüfung bereits während der Erstellung bringt Sicherheit und Zeitersparnis.

EBR (Electronic Batch Record)

Track & Trace

Die grafische Materialverfolgung erhöht die Transparenz und vereinfacht die Suche in jede Richtung. Sie deckt von der Anlieferung der Rohstoffe & Packmittel bis hin zur Verpackung das komplette Spektrum ab.

PA – Prozessanalyse (Golden Batch)

Darstellung von Abweichung in Bezug auf Referenzchargen. Unterstützung beim KVP (kontinuierlichem Verbesserungsprozess) hinsichtlich Schwachstellenanalyse und Prozessoptimierung. Erkennung von Tendenzen.

BI – Performance & Analyse (KPI / OEE)

Key Performance Indicator / Overall Equipment Effectiveness Implementierung entsprechend Industriestandard VDMA 66412-1 Unterstützung für Konfektionierung und Herstellung Manuelle / Automatische Erkennung und Erfassung des Betriebsmodus Oberfläche zur Analyse und Anzeige der KPI / OEE – Daten

EI – Unternehmens-Integration

Schnittstellen zu ERP / LIMS / DMS – Systemen auf Basis unterschiedlicher Standard-Technologien, wie z.B.:

- XML/SOAP Webservices

- B2MML

- Datenbanken

- OPC

- RFC / MII

- CSV / TXT