General information

- Ready-to-use, comprehensive, configurable and easy-to-use complete solution for the practically-oriented integration and automation of all production areas

- Tailored to production processes in the pharmaceutical, chemical, cosmetics and food sectors

- Scalable from a simple machine control to a complete MES system

- Combines MES- & PLS and SCADA-Functions in one system

- Electronic recording and documentation (ERB) according to FDA 21 CFR Part 11

- Ready-to-use software base guarantees a minimalized validation effort in the project

- Developed from the experience and requirements of production and practice

- Since 2005 worldwide with more than 1500 installations in productive use

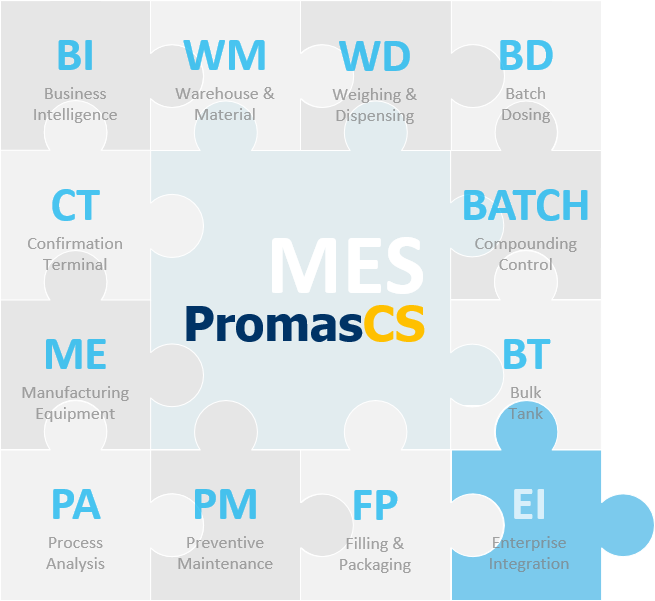

Modules of PromasCS

BD - Raw Material Tanks

- Fully integrated raw material tank management for reception and provision of raw materials

- Quantity registration at truck unloading

- Administration and monitoring of expiry dates

- Fully automated cleaning control via VisualProcess

- Monitoring states of cleaning and sterilization

BD – Central Dosing System

- Fully integrated dosing system for central raw material supply to compounding lines or dosing/tapping stations

- Coordination / prioritization of dosing requests

- Monitoring and locking in accordance to the expiry date

- Automatic interlock of raw materials tanks

WD / WM – Warehouse - Weighing - Dispensing

- Considers variations of active ingredients

- Considers the amount of ingredients based on previous weighing’s

- Expiry date monitoring / prioritization

- System guided calibration or working instruction

- Workflow guided weighing process

CT – Confirmation Terminal

- Integration of existing systems into the paperless documentation – without modification of the existing automation

- Electronic procedures instructs the operator step by step

- Execution is documented within the electronic batch record (EBR)

- Confirmation of raw material via barcode to ensure the right combination of batch and material

BATCH – Compounding

- Fixed size or scalable batching for reproducible processes

- Fully automated control of production and cleaning processes by self-created MBR (Master Batch Records) with VisualProcess

- Interlocking equipment in relation to the product & cleaning matrix

- Status of equipment can be monitored or set within the process

- Gap free documentation of all production steps (EBR)

BT – Bulk Tanks

- Management to store batches into solid / mobile bulk tanks

- Administration, calculation and monitoring of expiry dates

- Fully automated cleaning control via Visual Process

- Monitoring states of cleaning and sterilization

FP – Filling / Packaging

- Full integrated bulk supply to filling lines

- Automatic locking with quality release and cleaning state

- Definition and identification (Barcode) of packaging materials

- Identification of equipment (Barcode) for setting up filling lines

- Administration of electronic instructions for setting up, filling or cleaning filling lines

PM – Preventive Maintenance

- Administration of periodic tasks or operating counter based task to manage recurring services, maintenance or support tasks

- Increase of industrial safety, optimization of replacement intervals and reduction of unscheduled shutdowns

- Saving time and cost of materials

- System based documentation of the executed task

ME – Manufacturing Equipment

- Fully integrated equipment management to set and monitor states of manufacturing equipment

- Online evaluation of equipment status inside batching process

- Definition of machine independent workflows

- Supports Equipment Identification (e.g. Barcode, RFID)

MBR (Master Batch Record)

Creation of customized cleaning and production processes with the very useful support of HMI-flow charts and the flow diagram display to visualize the process. The simulation & plausibility checks while creating processes safes time and reduces errors.

EBR (Electronic Batch Record)

According to FDA 21 CFR Part 11 the One-Click batch report collects all relevant information of the selected batch. At a glance it can be seen whether the batch has deviations.

Track & Trace

Easy to follow graphical material tracking – from delivery of raw materials and packaging materials up to filling.

PA – Process Analysis (Golden Batch)

Display of deviations according to a reference batch. Supports the CIP (Continuous Improvement Process): Critical point analysis and process optimization. Detection of tendencies.

IPC / Labor - Quality

EI – Enterprise Integration

Interfaces to ERP systems based on different standard technologies like e.g.:

- XML/SOAP Webservices

- B2MML

- Datenbanken

- OPC

- RFC / MII

- CSV / TXT

Customer requirements

Special wishes? We implement additional modules into your overall system and adapt existing modules to your needs. No wish should be left open!